Our Products

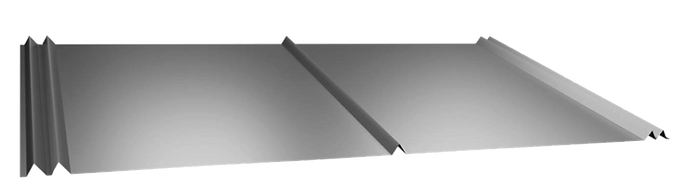

Mechanical Standing Seam Metal Roofing Profiles

Mechanical Standing Seam Metal Panels bring together advanced performance and classic elegance to create the ultimate roofing solution. Perfect for high-profile architectural projects, these panels are built to thrive in even the most demanding environments. A hidden clip system allows the panels to flex with temperature changes, preventing stress and maintaining a flawless look. Many systems can be produced on-site, offering dramatic, seamless lines that run uninterrupted from ridge to eave, enhancing both function and aesthetic.

150MSAllSeam

1-1/2″ Mechanical Standing Seam Panel

Seam: 90° or 180°

Substrate: 22-, 24-, 26-gauge steel,.032, .040 aluminum, or 16oz. and 20oz. copper

Slope: 2:12 or greater slope

Support: Wood deck 15/32-inch or greater plywood; or metal decking

Coverage: 12 inches, 16 inches, or 20 inches

Options: Curve Capable

Snap-Lok Clip Standing Seam Metal Roofing Profiles

The Snap-Lok Clip Standing Seam Metal Panel System combines sleek, modern aesthetics with the timeless appeal of continuous interlocking seams—without the need for mechanical seaming. Using a hidden clip system, panels are securely fastened to the roof deck and simply snapped into place, creating crisp, clean lines and a streamlined appearance. This innovative design not only enhances structural performance but also allows for superior thermal movement, making it an ideal choice for projects that demand both style and durability.

175SLAllSeam

1-3/4″ Snap-Lok Clip Standing Seam Panel

Seam Width: 1/2-inch, No mechanical seaming

Substrate: 22-, 24-, 26-gauge steel or .032, .040 aluminum

Slope: 2:12 or greater slope

Support: Wood deck 15/32-inch or greater plywood or steel deck

Coverage: 14 inches or 18 inches

155SLAllSeam

1-1/2″ Snap-Lok Clip Standing Seam Panel

Seam Width: 7/16-inch, No mechanical seaming

Substrate: 22-, 24-, 26-gauge steel or .032, .040 aluminum

Slope: 2:12 or greater slope

Support: Wood deck 15/32-inch or greater plywood, or 3/4-inch min. solid wood plank

Coverage: 12 inches, 16 inches or 20 inches

Snap-Lok Nail Strip Standing Seam Metal Roofing Profiles

Snap-Lok Nail Strip Metal Panels offer the clean, timeless look of standing seam roofing—at a more budget-friendly price point. Designed with simplicity in mind, these panels are fastened directly to the roof deck with hidden screws and easily snapped together without the need for clips or mechanical seaming. Their straightforward installation makes them an ideal choice for cost-conscious projects, while still delivering the long-lasting durability and performance expected from a standing seam metal roofing system.

150SLAllSeam

1-1/2″ Snap-Lok Nail Strip Standing Seam Panel

Substrate: 24-, 26-gauge steel or .032, .040 aluminum

Slope: 2:12 or greater slope

Support: 15/32-inch or greater plywood deck, or 3/4-inch minimum solid wood plank

Coverage: 15 inches or 19 inches

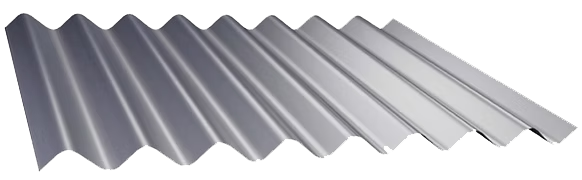

Exposed Fastener Metal Panel Roofing Profiles

Exposed Fastener Metal Roofing and Wall Panel Systems deliver the classic look of traditional metal panels, with the distinctive style of visible fasteners for a rugged, practical finish. Ideal for residential, agricultural, and light commercial use, these panels are praised for their ease of installation, versatility, and exceptional value. No special tools or seaming are required, and panels can be installed either vertically or horizontally—making them a perfect fit for roofs, walls, soffits, mansards, or even bold interior accents.

Built to withstand tough weather conditions, exposed fastener systems offer reliable, long-term performance. However, to maintain their integrity over time, a bit more routine maintenance is required compared to concealed fastener systems. Fasteners may gradually wear due to temperature shifts and UV exposure, so regular inspections and timely replacements are key to extending the life of your roof or wall system.

50AllV

1/2″ 5V Crimp Panel

Substrate: 24-, 26-gauge steel or .032, .040 aluminum

Slope: 3:12 or greater slope

Support: 15/32-inch or greater plywood, or 3/4-inch minimum solid wood plank

Coverage: 21 inches or 24 inches

Rib Spacing: 10-1/2″ or 12″ on center

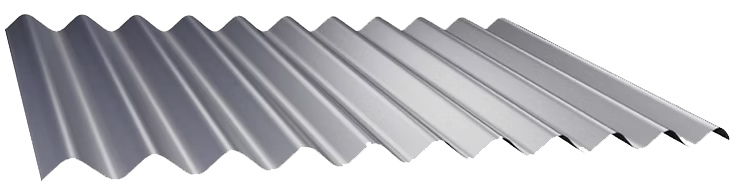

50AllRIB

3/4″ Trapezoidal Bell RIB Panel

Substrate: 24-, 26- or 29-guage steel

Slope: 3:12 or greater

Support: 15/32″ or greater thickness plywood, steel deck or open framing

Coverage: 36-inch (Standard)

Rib Spacing: 9″ on center